Nano-Micro-Particles Encapsulation

The cutting edge technology in nano health materials

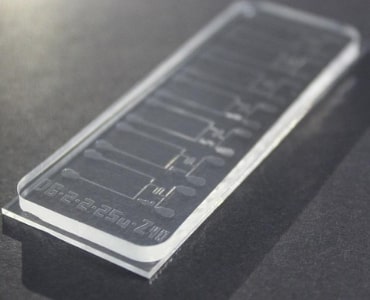

Our microfluidic chips are the heart of a robust, simple-to-use, and reliable platform for the production of organic nanoparticles using various materials given here. Why do we need microfluidic devices as 3rd generation technology in nano-encapsulation instead of previous old-generation methods? To compare our microfluidic technology and the conventional methods;

Innovative

This technology was designed exclusively by our researchers

Flexibility

Easy to set-up and modify parameters

| NEHİRBT MICROFLUIDIC NANO-ENCAPSULATION TECHNOLOGY |

Conventional Batch or High Pressure Homogenization |

|---|---|

| High quality particles and with low polydispersity index and smaller than 100 nm particle in size. |

leads to poor-quality particles and unreliable- inconsistent results. |

| Real-time control is available all the time during continuous flow synthesis. Any negative result can be re-optimized. |

are not field programmable with inability to control size in real-time. |

| Process is short and simple. Just plug the tubings of liquid sample and start the pump. In a few seconds, collect the nanoparticles. |

rely on long and complex batch processes with increased risk of failure. |

| Parallel microfluidic chips provide high volume manufacturing of nanoparticle with same procedure with single chips. |

are not suitable for easy scaling up with expensive and time-consuming re-optimisation. |

| The training of responsible users takes a day. (if have background on pharmaceutical formulations) |

are not user-friendly and requires expertise for operation. |

High Size Monodispersity

Low poly dispersity index

Precise

Reproducible particle fabrication specifications

Scalability

From 100 uL to hundreds of litres continuous production

Quality control tests of nanoparticle synthesis are available with various materials. Liposome, lipid nanoparticle, Soy Lecithin (Phosphotidylcholine), PEG-Polycaprolactone, Poly Lactic-co-Glycolic Acid (PLGA), and custom special materials are available in the graphs. The data for alginate, chitosan, and hyaluronic acid nanoparticles will be available soon.

Liposome nanoparticle size (nm)

Phosphotidylcholine nanoparticle size (nm)

PEG-Polycaprolactone nanoparticle size (nm)

PLGA nanoparticle size (nm)

KTÜ resin nanoparticle size (nm)

Size Distribution by Intensity

| AVAILABLE MATERIAL LIST FOR NANOPARTICLE GENERATION | |||

|---|---|---|---|

| Beta CycloDextrin, Nanosponge | Alginate | Caprolactone | Capsaicin |

| Agaros, low melting temperature | Chitosan | Collagen | Gelatin |

| Hyaluronic acid, crosslinked | Pectin | PLGA | PMMA |

| Liposomes and Lipid nano particles | Silk | Custom novel material | |

| Inorganic nanoparticles: magnetic, gold, quantum dots, silica etc... | |||

IN SUMMARY

NehirBT Nano-Micro-Encapsulation system achieves easy production by preserving the quality of particles at low and high volume level.

Step by step:

1. Aqueous phases of miscible/immiscible solvents containing precursors and antisolvents or crosslinkers are injected into each inlet of the microfluidic chip.

2. Under laminar flow, solvents immediately mix with help of special microfluidic channel structures.

3. Rapid, controlled, homogenous mixing produces homogeneous nanoparticles.

4. Collect the products realtime for further research.

To learn how NehirBT nano-micro-encapsulation system accelerates your nanomedicine development from an idea to clinical applications, contact our technical team.

Cost Saving

Reduced reagent cost

Customization

Multiple layer encapsulation ability

Speed

Rapid optimisation and re-optimisation

| TRY A DEMO | |

|---|---|

| CONTACT US | |

| Are you interested in implementing nanoencapsulation technology for your new commercialization plans or research projects? | Do you want a clearer and more representative indication of nano and micro encapsulation for your current products and research studies? |

| Whether you have tried microfluidics technology before or not, do you need workshops to understand better? | We are open for collaborations and demonstrations of synthesis of nano and micro particles with your materials on your site. |

Our microfluidic chips are the heart of a robust, simple-to-use, and reliable platform for the production of organic nanoparticles using various materials given here. Why do we need microfluidic devices as 3rd generation technology in nano-encapsulation instead of previous old-generation methods? To compare our microfluidic technology and the conventional methods;